Case Study - BIM pilot project of Latvia

BIM emerges in Latvian public sector - pilot project highlights

Project facts

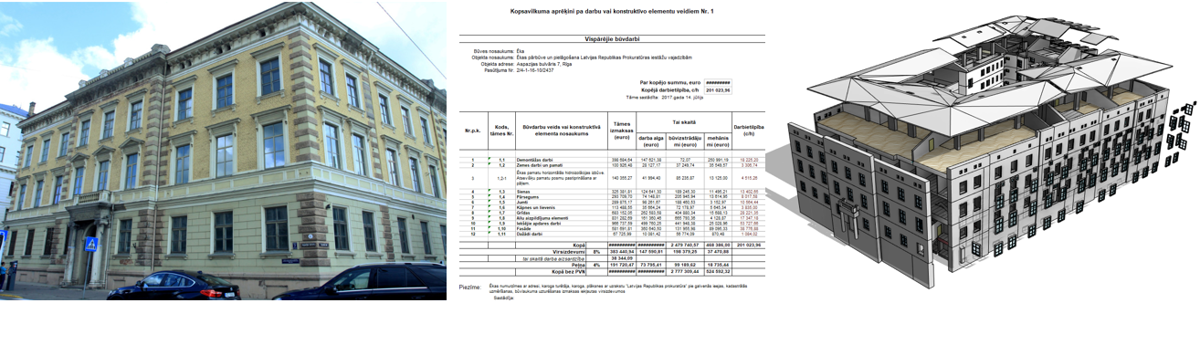

Main facade before refurbishment

Main facade before refurbishment

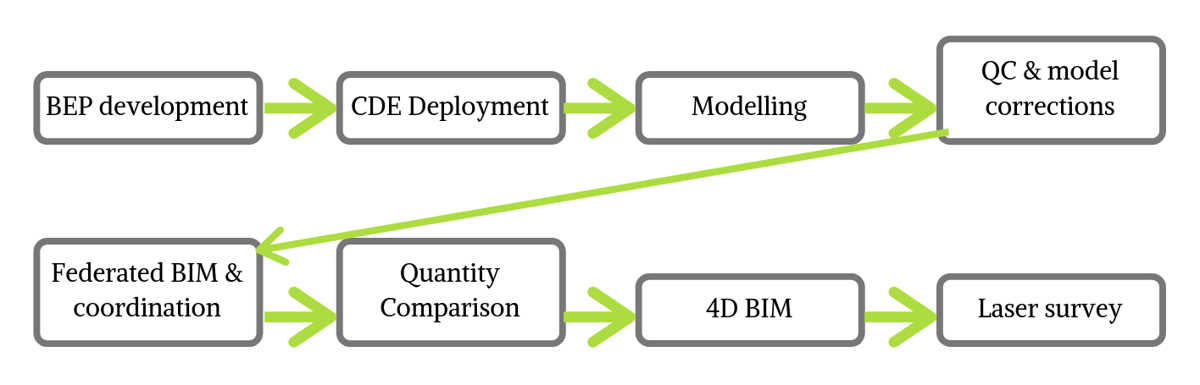

Deliverables, work packages and activities

BEP & CDE

Modelling

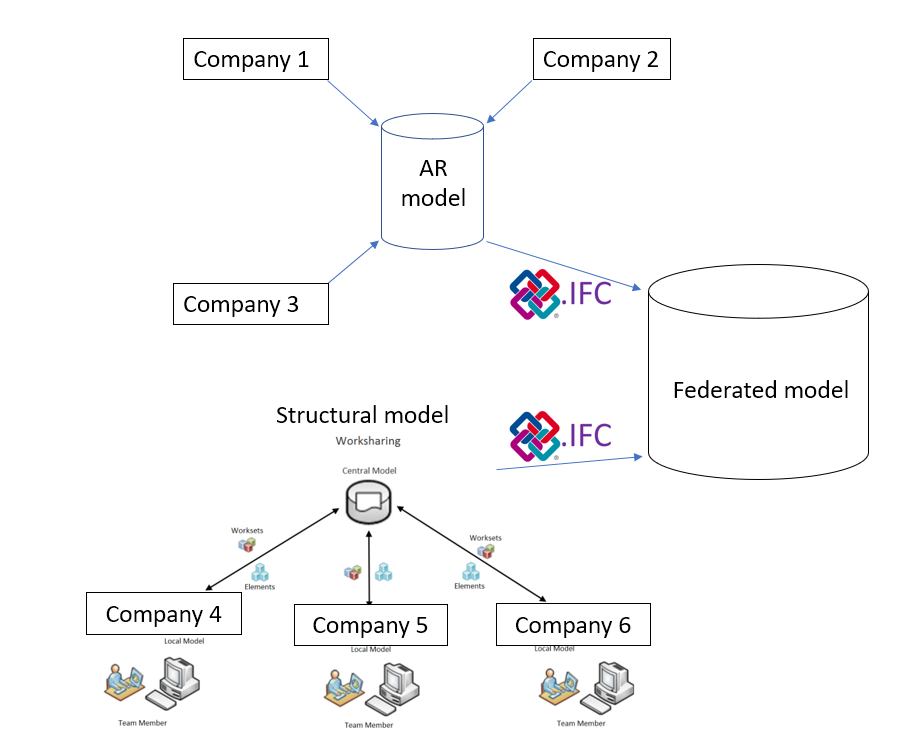

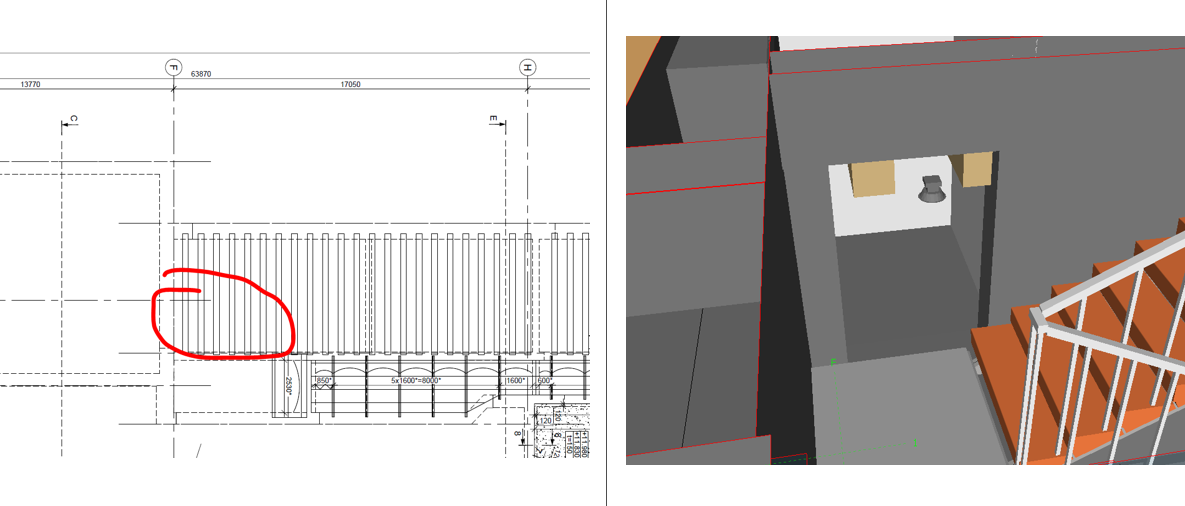

Woksharing between companies using Revit

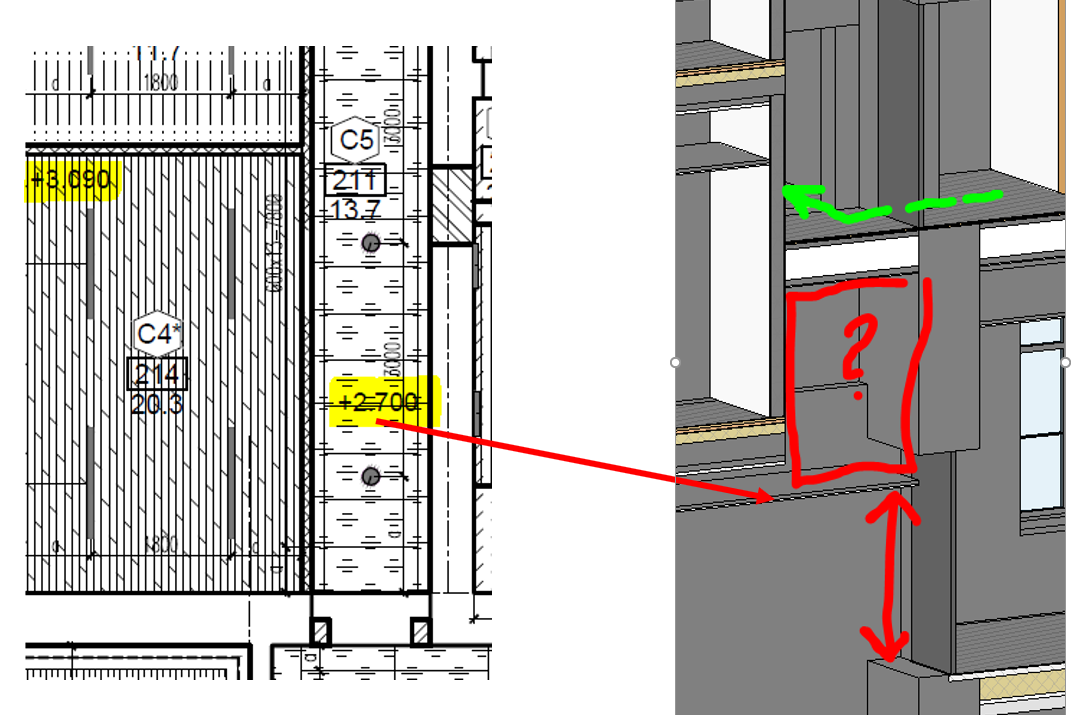

Celings in front of doors

Celings in front of doors

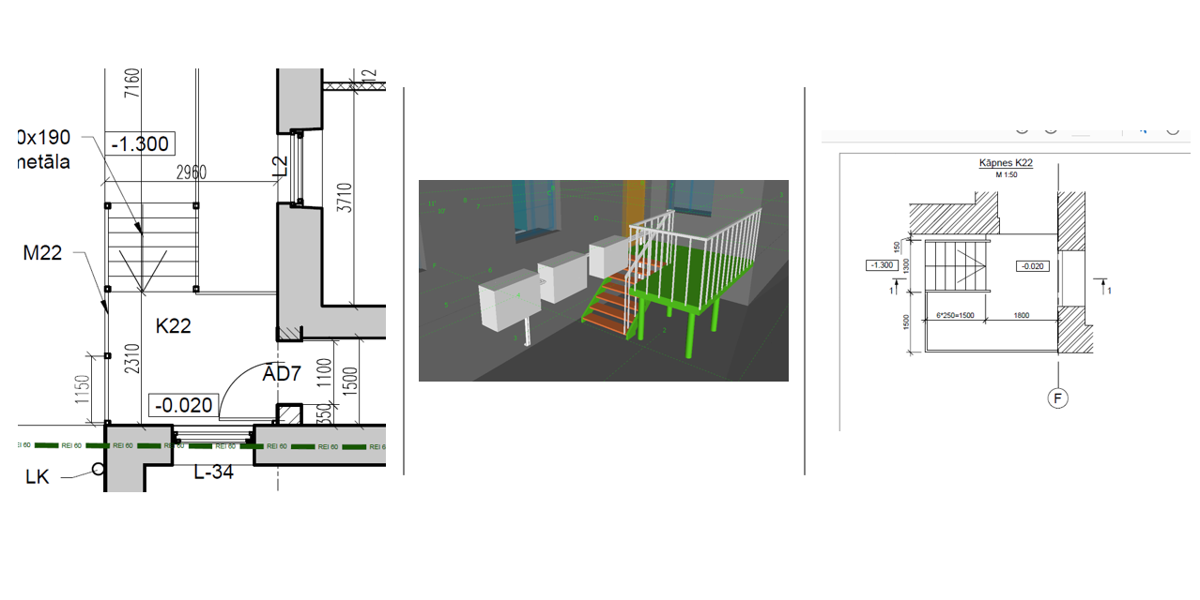

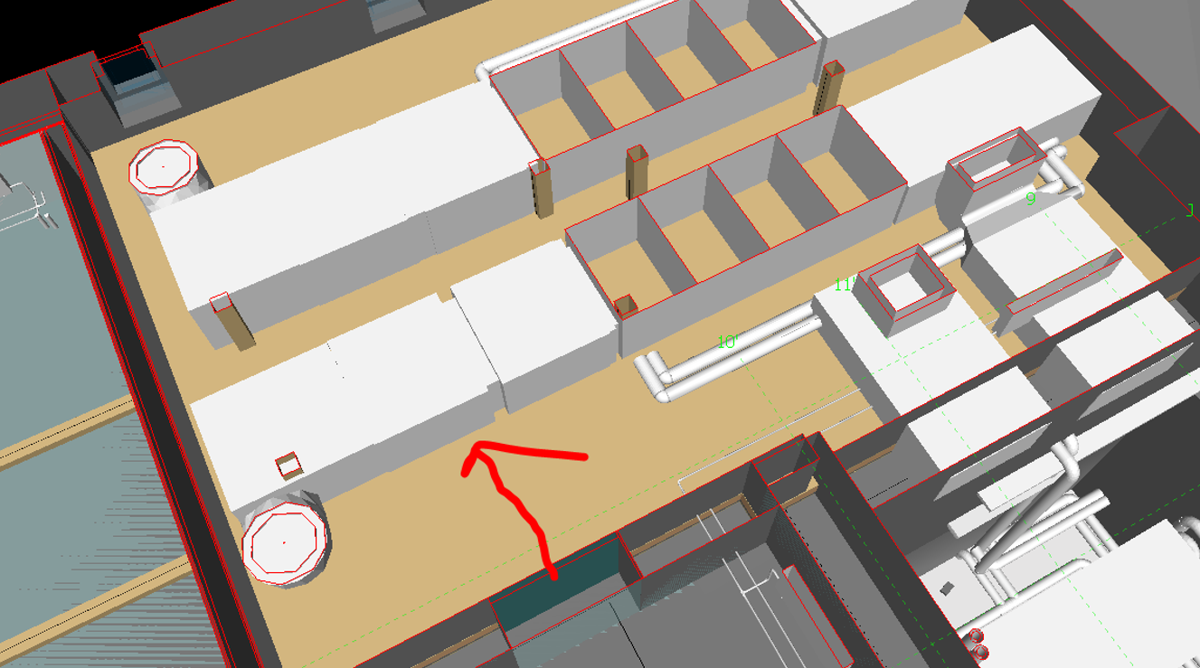

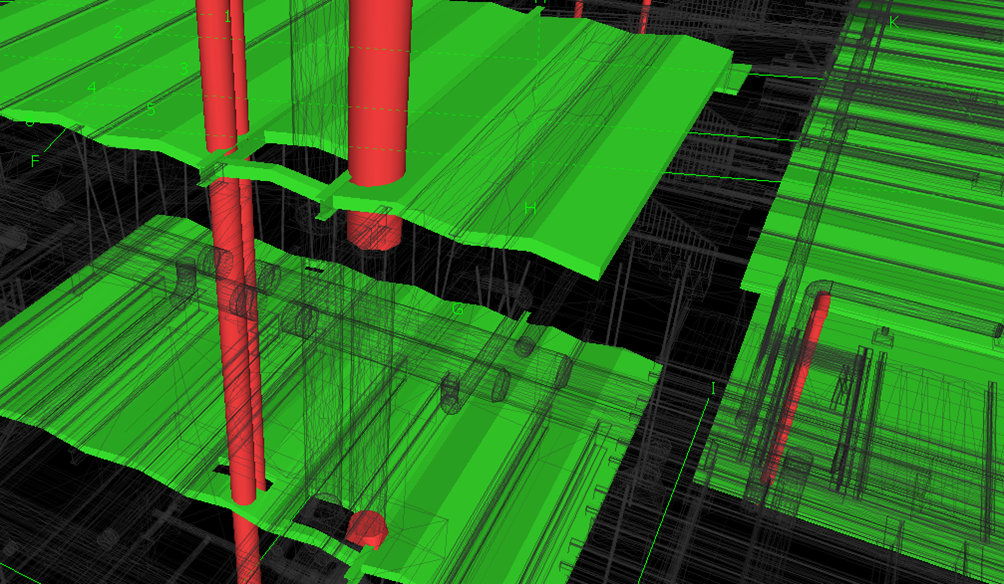

BIM coordination

Structural elements outside of the roof

Differences between architectural and structural drawings in the same location

Differences between architectural and structural drawings in the same location

Levitating structural beams

Mechanical equipment colliding with structural elements and blocking way

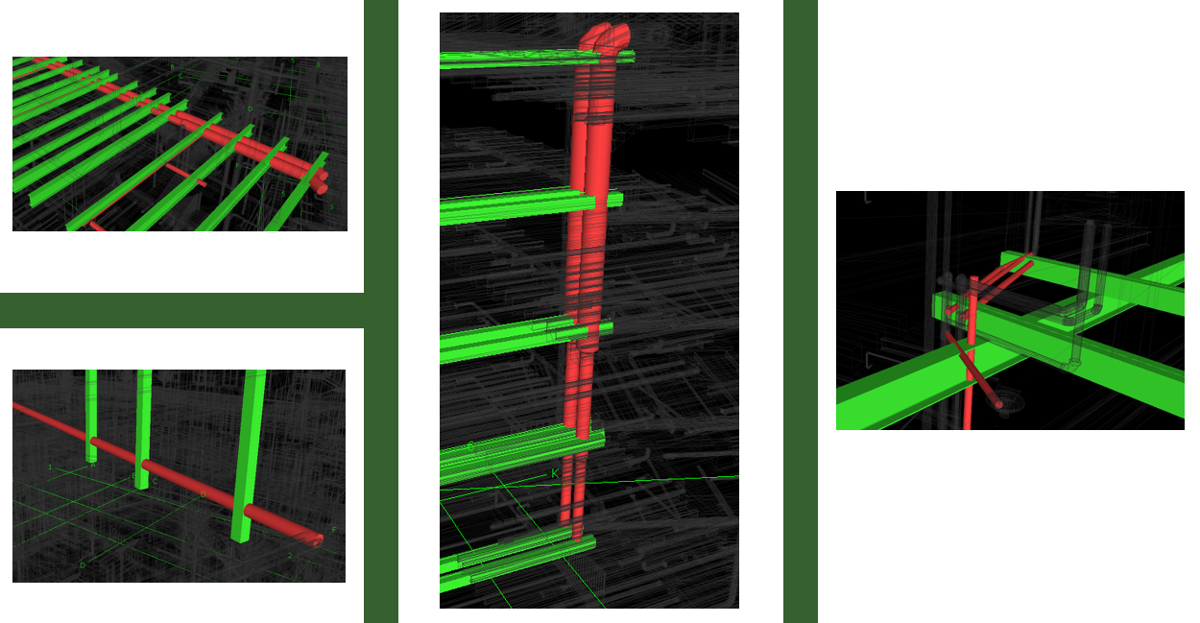

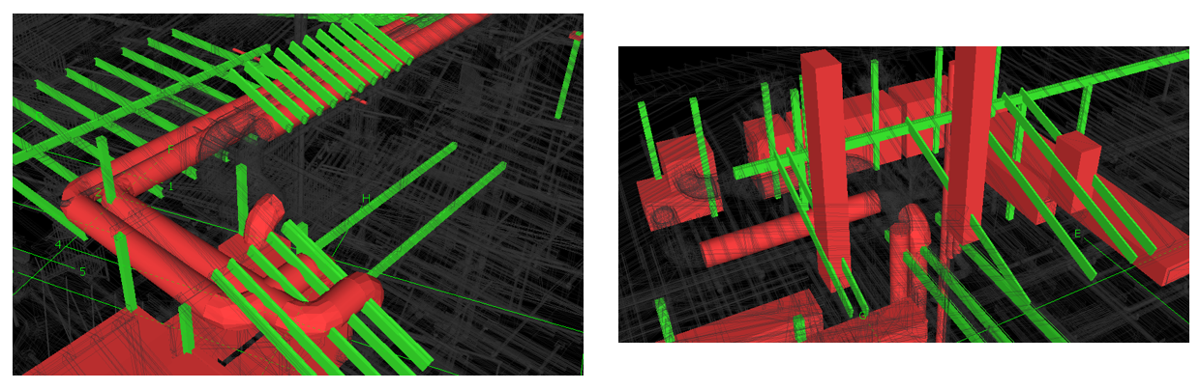

Clashes between pipes/ducts and structural objects

Clashes between ducts and structural objects

Misplaced structural openings

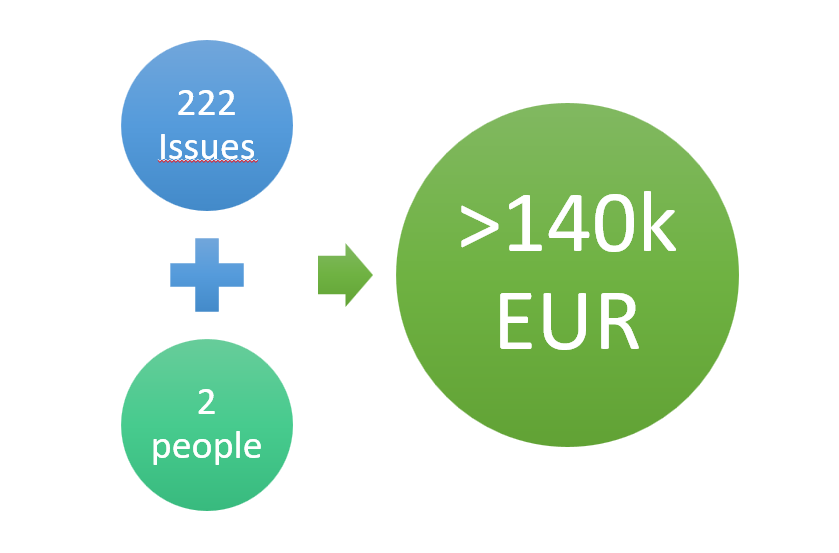

In total, 40 issues were identified during visual coordination and 180 during automated clash detection. Most of the issues were replicated across the building, and one group could include hundreds of similar clash instances across the building, for example, pipe clashes in the same model.

A simple estimate shows that dealing with these issues on-site costs a significant amount of money. The assumption was made that one issue can be resolved by 2 people in 2 days. In total it results in 7104 h spent. With an hourly rate of 20 EUR solving these issues would cost more than 140k EUR.

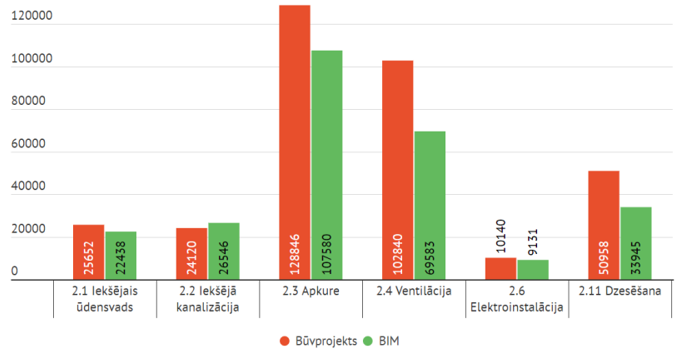

Quantities comparison

- Models precisely represent the design solutions

- It is impossible to compare all of BOQ positions with BIM. BIM and design were with different detail levels.

- Only physical volumes were compared. Labour costs and effort were not tested.

- Human errors can be reduced significantly by using structured information

- Data Science can be used to make better decisions which are based on information stored in BIM

- The average delta for quantities between models and BOQ exceeded 10%

4D BIM

Laser survey

Wall location differences comparing point cloud with BIM

Overall conclusions

- It is expensive not to use BIM. 10-20% costs could be saved by better design, coordination and planning.

- Traditional 2D methods are insufficient. It is nearly impossible to coordinate design without 3D models.

- The Pilot defined only a few BIM uses. In reality, there are hundreds, that can deliver value to the projects.

- Laser survey is an obligatory technology for reconstruction projects. The initial costs are outweighed by the avoidance of losses due to design errors.

- Great quality and results require strong competence on both sides - the client and the supply chain.

Continuation

The Pilot proceeds with an as-built model development. More conclusions will be made and we will write about them. Leave a note if you want to hear about the second phase.

Conclusion

ITED's team was responsible for the project management, MEP model development and 5D scheduling in for this project.

If you want to know more about how to get the benefits for you projects schedule a meeting with us!

Want to know more? Contact us!